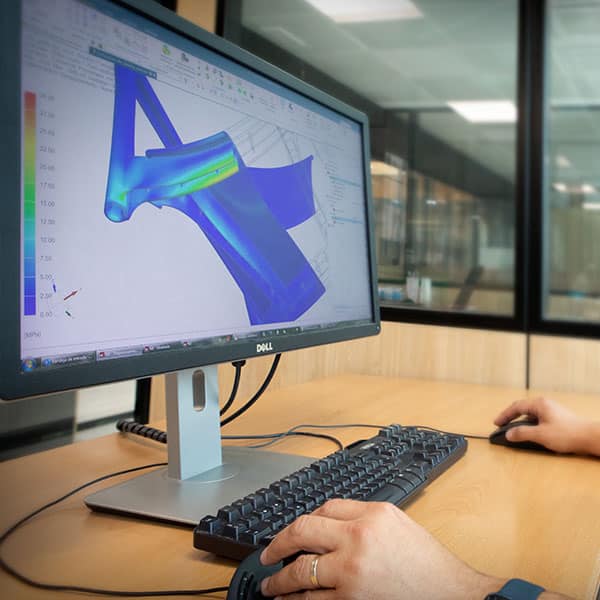

This in-house Technology Centre was created for the purpose of providing a complete R+D service. Our comprehensive product development process includes all aspects, ranging from conceptual design and mould construction and finishing with the launching of the product on the market.

Innovation is developing unique and successful ideas that also provide added value.

Innovation involves applying creativity when generating new products and improving current work processes.

Sp-Berner implements innovation methodologies in all of its business processes to create new products with high added value.

5 innovation levers for 2023-2025

While developing new approaches to our work, we have identified five levers of interest. Through these five distinct vantage points, we observe reality and search for solutions in the launching of new products.

New polymers and challenges in the supply chain. New regulation.

New manufacturing methods and new prototyping processes. Customisation and digitalisation. Artificial intelligence.

Democratisation of design, based on consumer experience. Aesthetic awareness, minimalism. Shifts in expectations.

Modularity, flexibility. Convenience and comfort. Accessibility and inclusiveness. Reduced lead times.

New and greener materials (reusable and refillable). Pay-per-use and Service Economy.

From the moment they rise until they go to bed, our consumers are multi-category. They have innumerable moments of contact with products belonging to our different product ranges and others that we potentially could enter into.

By accompanying them throughout the day, we detect their needs at all times. This allows us to identify development opportunities for new products to provide them with solutions.

Our innovation is based on consumer trends and research into new materials, processes, technology and eco-research.

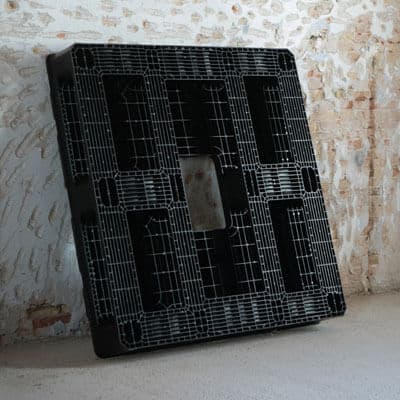

As a leading company in the sustainable plastics processing sector, SP-Berner faces the challenge of continuous and constant innovation in product quality.

Sp-Berner always strives for the utmost quality in all its systems and is strongly committed to research and development.

Commitment and the pursuit of excellence are the key to the company’s success. This includes the acquisition of raw materials, the use of the latest technology in the manufacturing processes and the final presentation to the consumer.

These efforts symbolise the genuine commitment of all the people involved in our manufacturing and development processes, making Sp-Berner a leader in safety and innovation in product quality.

Sp-Berner complies with strict and rigorous quality controls on its raw materials, processes and finished products: