Sp-Berner’s Innovation and Sustainable Packaging division seeks to reduce its environmental footprint and redesign the future of the sector with its 360º strategy.

360º Projects and Innovation and Sustainable Plastic Packaging

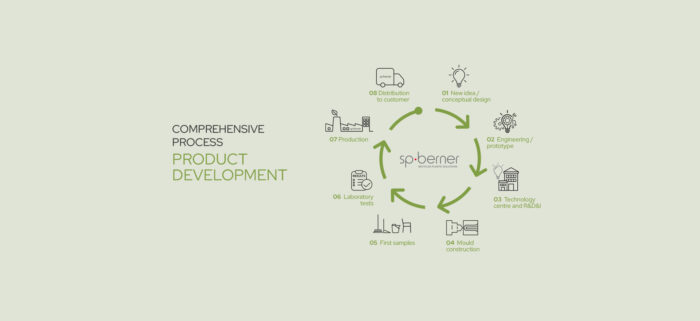

For Sp-Berner, innovation is a philosophy that runs through the entire product life cycle. Our 360º strategy is understood as a comprehensive and proactive analysis of each project from every possible perspective, taking into account its functionality, environmental impact, resource efficiency and consumer experience.

But when we talk about a 360º project, it goes much further. It means that optimisation is present in every phase:

- Design. Structures are optimised for weight and recycling.

- Materials. The most sustainable options are selected (recycled, bio-based, single material).

- Production and logistics. Energy efficiency and reduced transport.

- Use and recycling. Facilitate separation and the recycling process at the end of the product’s useful life.

This means that every decision, from the thickness of the plastic to the type of label or printing, is aimed at minimising environmental impact and facilitating the circularity of the packaging. And for this to be carried out correctly, seamless cross-functional collaboration is required from internal departments, suppliers and customers alike.

What are our short- and medium-term objectives?

On the one hand, in the short term, we are focusing on ‘intensification’ (uniform, defect-free packaging components). At Sp-Berner, we are continuously increasing both the percentage of recycled material and the integration of new sustainable materials such as bio-based materials, while always guaranteeing maximum quality and safety.

On the other hand, in the medium term, we want to consolidate a fully circular product model. Where each design is conceived for its return to the production cycle.

Materials that make a difference

In recent years, we have made significant strides in incorporating post-consumer recycled materials into our packaging solutions. Today, a considerable portion of our catalogue includes products containing between 30% and 100% recycled plastic.

In parallel with this, we are exploring the potential of bio-based materials derived from renewable sources that reduce dependence on fossil resources.

What are the current challenges facing sustainable packaging in the plastics industry?

There is increasing awareness and commitment, leading to a positive response from end consumers and customers to this type of packaging. The brands we work with at Sp-Berner value being able to offer products that combine sustainability, design and quality.

However, this sector still faces significant challenges. One of the main ones is achieving a functional and economic balance between sustainability, functionality and cost. Technical and regulatory barriers still exist to the widespread use of materials such as compostable or some recycled materials, compounded by the need to improve the overall collection and recycling infrastructure.

At Sp-Berner, we are convinced that full collaboration across the value chain – from manufacturers and institutions to distributors and consumers – is the only way to overcome these obstacles.

Success story

One of our most notable examples has been the development of single-material caps with an innovative technical solution for food applications. Their structure has been optimised to reduce weight without compromising strength, making the caps easy to recycle.

In short, thanks to innovation in design and materials, we have managed to maintain functionality and aesthetics while reducing the consumption of virgin raw materials.

Some of our sustainable packaging developments have enabled us to reduce product weight by up to 20%, thereby also reducing associated CO2 emissions. Using recycled plastic saves energy and resources, reinforcing our commitment to the Sustainable Development Goals and to decarbonising the sector.

In conclusion, Sp-Berner’s commitment to the 360º strategy transforms plastic packaging into a valuable tool that is not only functional but also environmentally responsible.