At SP-Berner, our history began with the vision and tireless work of one family. That small seed planted more than 60 years ago has blossomed, generation after generation, to become a solid and innovative company, leaders in southern Europe in plastic injection moulding. But beyond numbers and expansion, what really drives us is a fundamental purpose: to offer the best product and to promote the circularity of plastic.

Where commitment takes form: our recycling plant

More than a decade ago, that purpose materialised in our 72,000 m2 recycling plant in Torrent, Valencia. Here, post-consumer plastic is not just waste, it is not the end of the line. For us, it is a resource. It is a valuable secondary raw material to which, with dedication and technology, we seek to give a new function. Our goal is ambitious and clear: to significantly increase the use of recycled plastic in our production, currently more than 20,000 tonnes of post-consumer plastic are used annually. Therefore, a substantial part of our products incorporate material recovered in our own facilities.

The real journey: from recovered resource to useful product

Imagine the journey. Every day, tons of plastic arrive on our doorstep. What for many is ‘waste’, for us is an opportunity. With advanced technology and the talent of more than 800 committed professionals, we orchestrate a process of transformation:

- Reception and pre-sorting: each batch of post-consumer plastic entering our facilities undergoes an initial sorting to ensure that the material is suitable for our recovery process.

- Rigorous washing: the plastic undergoes a thorough washing process to minimise impurities and contaminants, ensuring the material is properly prepared.

- Separation and preparation: once cleaned, the plastic is separated by type and crushed into small particles, known as flakes. This step is crucial to achieve the homogeneity required for the next process.

- Revaluation by extrusion: the plastic flakes are then melted and extruded, forming yarns which are subsequently cut into small granules. It is these recovered plastic granules that are ready to be re-incorporated into the manufacture of new products.

This integrated process allows us to recycle internally a significant part of the post-consumer plastic we use, reincorporating it into our production chain.

This makes us the only manufacturer that recycles, processes and reuses post-consumer plastic in-house, with full control over the entire process.

Continuous innovation and quality in every design

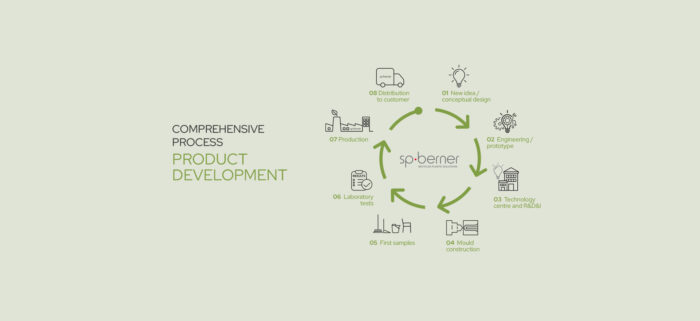

At SP-Berner, innovation is a constant pillar. We research and develop solutions to optimise our recycling and processing processes. Our aim is to ensure that our products, in addition to incorporating recovered materials, maintain the highest standards of quality and functionality. In our designs, we strive for effectiveness and efficiency: products that are light, resistant, simple and designed for everyday use.

We also recognise the importance of energy management. That is why we are aiming for an increasing share of our energy consumption to come from renewable sources in the coming years. Currently 54% of the energy we consume comes from renewable sources.

Beyond the factory: products that come to your home and to more than 50 countries

From our plant in Torrent, our products start their journey to adapt to the daily lives of millions of people. They reach more than 50 countries and are present on the main shelves of the largest international retailers.

In our wide range, you will find everything from airtight storage for your kitchen to reusable kitchenware, from cleaning products and toothbrushes and hairbrushes to home organisers and industrial solutions such as folding boxes or custom-made items. Even attractive outdoor furniture and portable coolers for enjoying the great outdoors. Every product that leaves our hands reflects SP-Berner’s commitment to quality and the pursuit of more circular solutions.

At SP-Berner, we are building a path where every piece of plastic is an opportunity for a future with less waste.